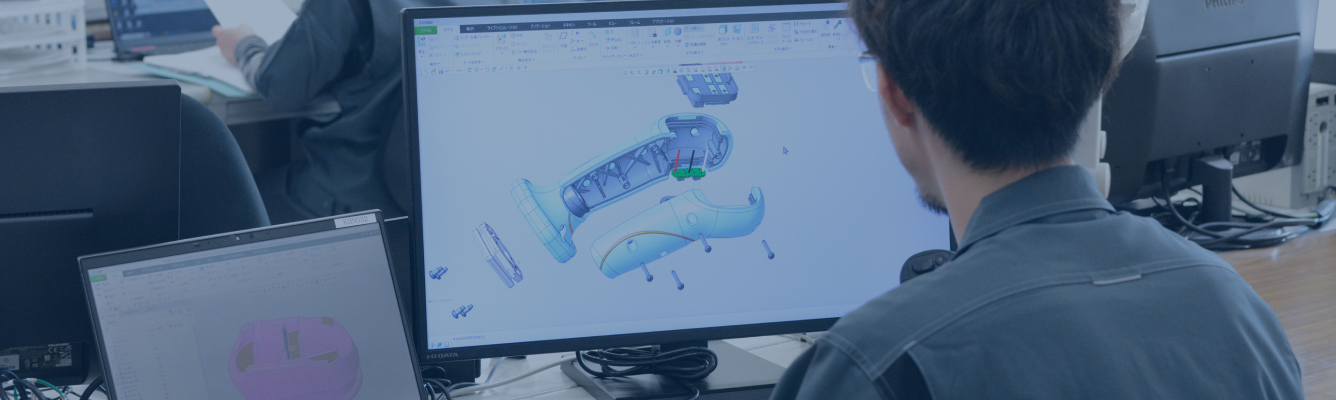

YEC Feature Joint Development with Major Japanese Corporations

From passenger cars to special purpose vehicles, we respond with reliable parts.

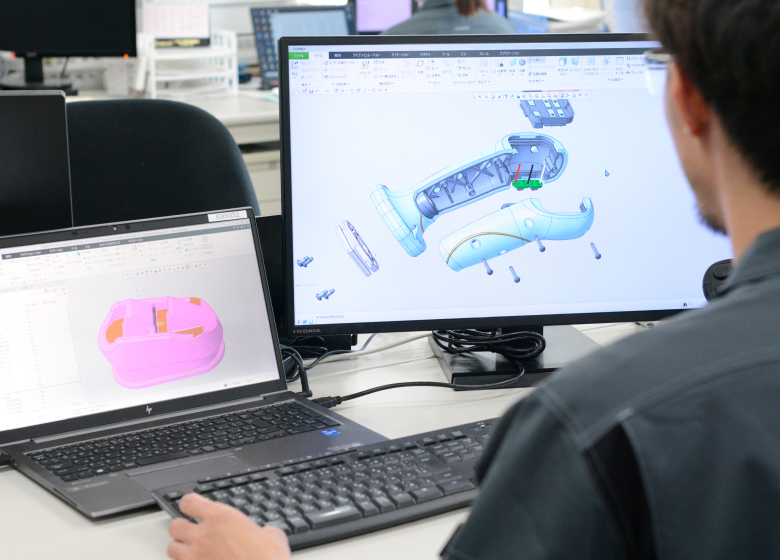

Yamaguchi Electric Industry develops genuine parts for new vehicle models in collaboration with various vehicle manufacturers in Japan. Based on basic specifications, we respond to a wide range of development requirements, including testing the incorporation of new components, functionality proposals, and quality checks.

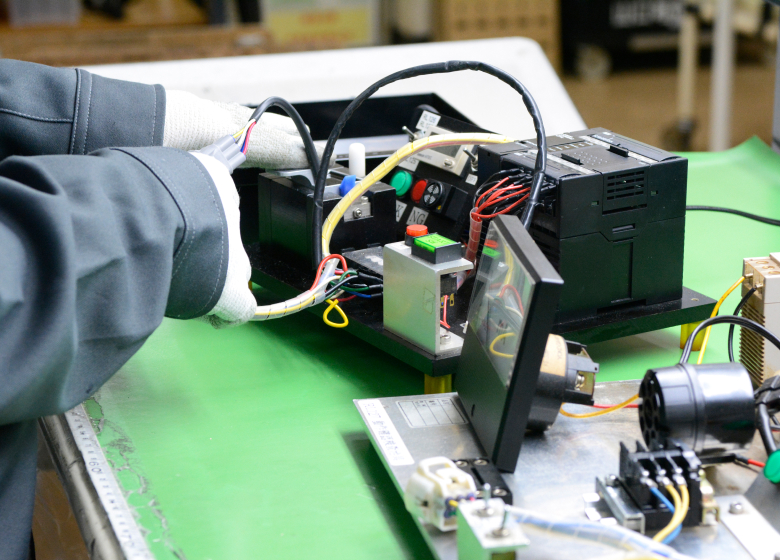

We are involved in the development of parts for a wide range of vehicles, including not only passenger cars but also trucks, industrial machinery, construction machinery, agricultural machinery, and special purpose vehicles, and we have built a system that can meet the different specifications required by each application and strive to provide customer-focused service.

YEC supplies genuine car parts designed and developed jointly with automakers

In partnership with a wide range of major Japanese automakers, YEC develops all types of alarms, switches and other genuine parts for new car models, a process that takes one to two years to complete. Building on basic specifications like size and design, we respond precisely to diverse development needs, conducting tests with new components installed in vehicles, providing proposals for improved functionality, and verifying quality.

Our products are found in a wide spectrum of vehicles including trucks, industrial and construction machinery and special purpose vehicles

Vehicle manufacturers engaged in joint development with Yamaguchi Electric Industries are manufacturers not only of passenger vehicles, but also of a broad spectrum of vehicle types including trucks; industrial, construction, and agricultural machinery; and special purposetrucks (fitted with special equipment, such as cranes). YEC can precisely meet a diverse range of specification requirements tailored to particular applications.

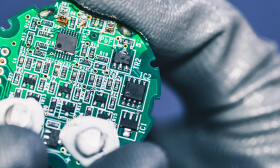

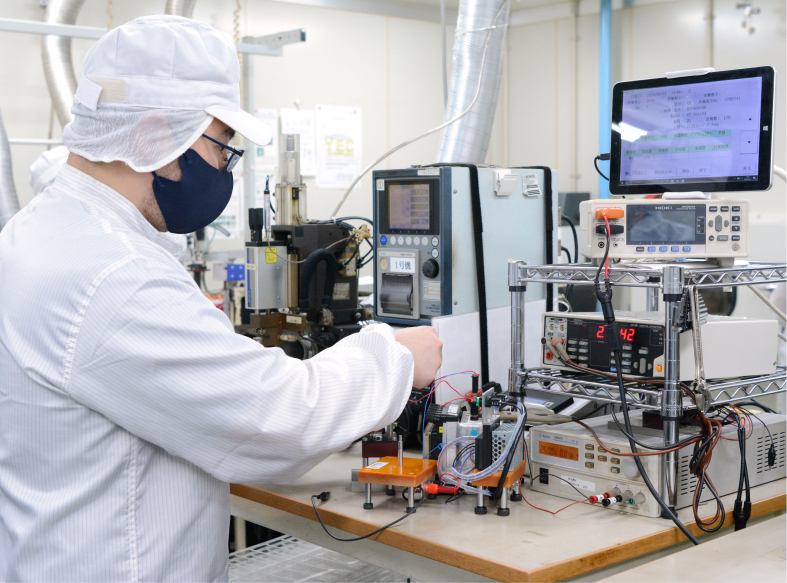

Production systems that give our parts manufacturing a competitive edge

YEC manufactures parts at two factories, in Akita Prefecture (Japan) and in China. For products subject to particularly strong cost-reduction demands, we have put a production line in place at our China Plant that is capable of maintaining top quality while staying cost-competitive, helping to meet the diverse needs of automakers.

Contracted production orders filled at our China Plant

Thanks to our reliable production line, YEC can fulfill orders from automotive component manufacturers both in Japan and abroad to produce parts under contract at our China Plant. Parts manufacturers considering cutting costs through overseas production are encouraged to contact us for information.

-

Switch Related Products

-

Air conditioning duct